Heating, generation, standby generation plant, road vehicle or marine vessel fleet

You are probably unaware that the fuel oil you are delivered for your heating plant, standby generation plant or vehicle/vessel fleet will not conform to the ISO 4406 standard of cleanliness.

Burning dirty fuel is detrimental to the systems in which it is burned, shortening component life, and increasing O&M costs.

Burning dirty fuel is also a major cause of toxic emissions being released into the atmosphere.

Offline fuel oil filtration prior to use will deliver a clean burn, increasing meantime between component failure, reduce O&M costs and reduce emissions.

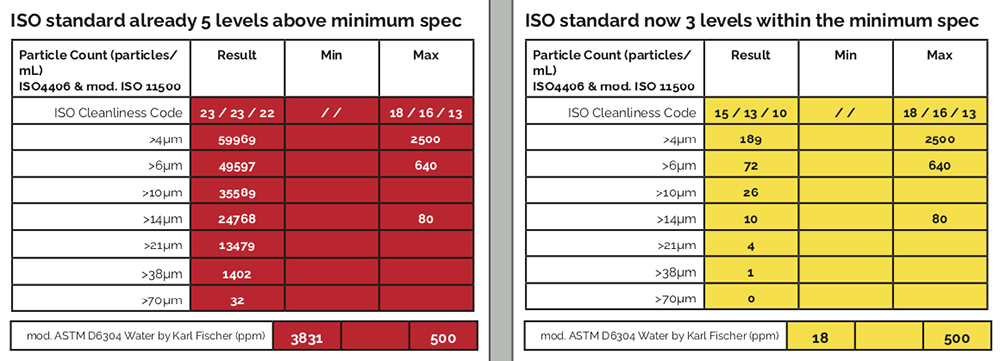

The example below shows what a simple addition of a DX Power Train System to your fleet fuel management system will make to the fuel you burn and the health of your oil burning plant.

The chart on the left shows the condition of the fuel in the storage tank before the application of the Delta-Xero Power Train System. The fuel exceeds the minimum ISO 4406 Standard of 18/16/13 by some 5 cleanliness levels and has high moisture content well above the 500ppm maximum for fuel oil.

The chart on the right shows the same tank six days after the installation of a Delta-Xero Power Train for fuel system. The oil is already well within the ISO 4406 standard by some three cleanliness levels and the moisture content is now well below the 500ppm limit at 18ppm.

All data used is independently verified and analysis provided by independent laboratories.

Do something positive for your business and the environment.

Visit Delta-Xero on stand 6004 at the Distributed Energy Show and find out how the Delta-Xero Power Train and oil filtration range can reduce your O&M costs and your carbon footprint.

david@delta-xero.com